Corrugated ring hose made of stainless steel Type HDA

Description

Type HDA –> Material: AISI 316L

Application

- As high pressure hose at particularly high pressure levels for conducting steam, water, oil, compressed air and oxygen

- For carrying aggressive media

Hose design

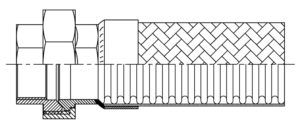

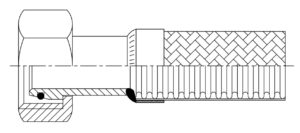

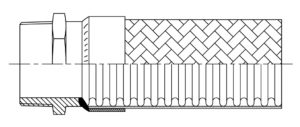

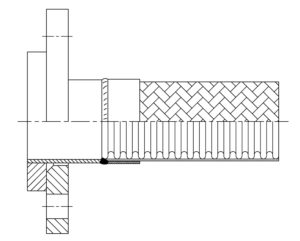

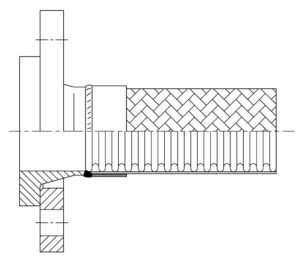

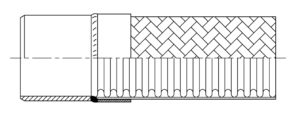

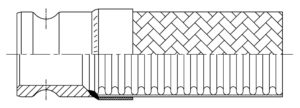

- Normal corrugated Full metal hose made of butt welded pipe, Heavy duty

- Hose can be provided with no, one or two stainless steel braiding

- Production according EN / ISO 10380

Material

- Hose standard: AISI 316L

- Braid standard: AISI 304

Temperature

- From- 196°C up to max. + 600°C

Also possible

- With DVGW acceptance

- CE sign as per the pressure equipment directive (97/23/EC)

- As per DIN 2827

- With external Agraff or spirals to protect against abrasion

- With internal Agraff hose or braiding as flow conductor

- With flanged recoil lock

- With PTFE inner lining

- Special designs at customer request

* Please refer to our resistance list in the download area

Technical Data

| Internal-Ø | Braid | External-Ø | Pressure (bar) | Bending radius | Weight |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | Inch | Quantity | mm | Tolerance +/- | Pressure PN | Working Pressure SF* 4 | Working Pressure SF* 3 | Burst | stat. | dyn. | kg/m |

| 6 | 1/8" | 0 | 10.2 | 0.1 | 50 | 50 | 66 | 200 | 15 | 60 | 0.12 |

| 1 | 11.6 | 160 | 200 | 266 | 800 | 25 | 0.30 | ||||

| 2 | 13.0 | 250 | 250 | 333 | 1000 | 40 | 0.42 | ||||

| 8 | 1/4" | 0 | 12.8 | 0.1 | 25 | 30 | 40 | 120 | 16 | 124 | 0.15 |

| 1 | 14.5 | 160 | 200 | 266 | 800 | 32 | 0.32 | ||||

| 2 | 16.1 | 250 | 250 | 333 | 1000 | 50 | 0.48 | ||||

| 10 | 3/8" | 0 | 16.0 | 0.1 | 25 | 30 | 40 | 120 | 18 | 130 | 0.17 |

| 1 | 16.9 | 150 | 150 | 200 | 600 | 38 | 0.34 | ||||

| 2 | 18.5 | 160 | 200 | 266 | 800 | 60 | 0.52 | ||||

| 12 | 1/2" | 0 | 17.0 | 0.2 | 25 | 30 | 40 | 120 | 20 | 140 | 0.20 |

| 1 | 18.7 | 100 | 100 | 133 | 400 | 45 | 0.38 | ||||

| 2 | 20.3 | 160 | 200 | 266 | 800 | 70 | 0.56 | ||||

| 16 | 5/8" | 0 | 21.8 | 0.2 | 20 | 20 | 26 | 80 | 28 | 160 | 0.28 |

| 1 | 23.8 | 150 | 150 | 200 | 600 | 58 | 0.57 | ||||

| 2 | 25.8 | 160 | 200 | 266 | 800 | 90 | 0.86 | ||||

| 20 | 3/4" | 0 | 26.6 | 0.2 | 6 | 6 | 8 | 24 | 32 | 170 | 0.43 |

| 1 | 28.6 | 63 | 65 | 86 | 260 | 70 | 0.67 | ||||

| 2 | 30.6 | 100 | 100 | 133 | 400 | 70 | 1.00 | ||||

| 25 | 1" | 0 | 32.3 | 0.2 | 6 | 6 | 8 | 24 | 40 | 190 | 0.54 |

| 1 | 34.3 | 50 | 50 | 66 | 200 | 85 | 0.93 | ||||

| 2 | 36.3 | 100 | 100 | 133 | 400 | 85 | 1.33 | ||||

| 32 | 1 1/4" | 0 | 41.1 | 0.3 | 4 | 4 | 5 | 16 | 50 | 260 | 0.69 |

| 1 | 43.0 | 63 | 65 | 86 | 260 | 105 | 1.18 | ||||

| 2 | 45.2 | 63 | 65 | 120 | 360 | 105 | 1.70 | ||||

| 40 | 1 1/2" | 0 | 49.6 | 0.3 | 2.5 | 2.5 | 3 | 10 | 60 | 300 | 1.10 |

| 1 | 52.0 | 40 | 40 | 53 | 160 | 130 | 1.65 | ||||

| 2 | 54.2 | 63 | 65 | 86 | 260 | 130 | 2.24 | ||||

| 50 | 2" | 0 | 60.5 | 0.3 | 2.5 | 2.5 | 3 | 10 | 70 | 320 | 1.42 |

| 1 | 62.4 | 50 | 50 | 66 | 200 | 160 | 2.25 | ||||

| 2 | 65.5 | 63 | 65 | 86 | 260 | 160 | 2.98 | ||||

| 65 | 2 1/2" | 0 | 80.6 | 0.3 | 0.5 | 0.5 | 0.5 | 2 | 115 | 460 | 2.08 |

| 1 | 83.5 | 25 | 25 | 33 | 100 | 200 | 3.29 | ||||

| 2 | 86.6 | 50 | 50 | 66 | 200 | 200 | 4.50 | ||||

| 80 | 3" | 0 | 97.8 | 0.3 | 0.5 | 0.5 | 0.5 | 2 | 130 | 660 | 2.45 |

| 1 | 100.2 | 16 | 16 | 21 | 64 | 240 | 3.72 | ||||

| 2 | 103.3 | 25 | 25 | 33 | 100 | 240 | 4.91 | ||||

| 100 | 4" | 0 | 119.8 | 0.5 | 0.5 | 0.5 | 0.5 | 2 | 160 | 750 | 3.36 |

| 1 | 122.5 | 10 | 10 | 13 | 40 | 290 | 5.07 | ||||

| 2 | 125.6 | 16 | 16 | 21 | 64 | 290 | 6.78 | ||||

SF = Safety Factor

With a safety factor of 4, the hose has a 4-times safety of the max. permissible working pressure.

This safety factor conforms the DIN and EN- regulations.

The given operative data in the table refer to an ambient temperature of +20°C.

Please note our reduction factor.

→ On request other sizes, further materials and special versions